Please include any relevant https://www.achievementlearn.com/ details about your picture, including desired image size, and another data you think we should always know. You can submit any artwork that could be opened with the Adobe® suite of products. Holden's Screen Supply display making companies produce top quality business grade pre-burned silkscreens. Screen dimensions include the frame, which consists of 1.5" broad aluminum partitions. Wooden frames are a wallet-friendly option, however they’re not as sturdy or sturdy as other kinds of frames. Metal frames are stronger and extra sturdy, great for all-purpose jobs.

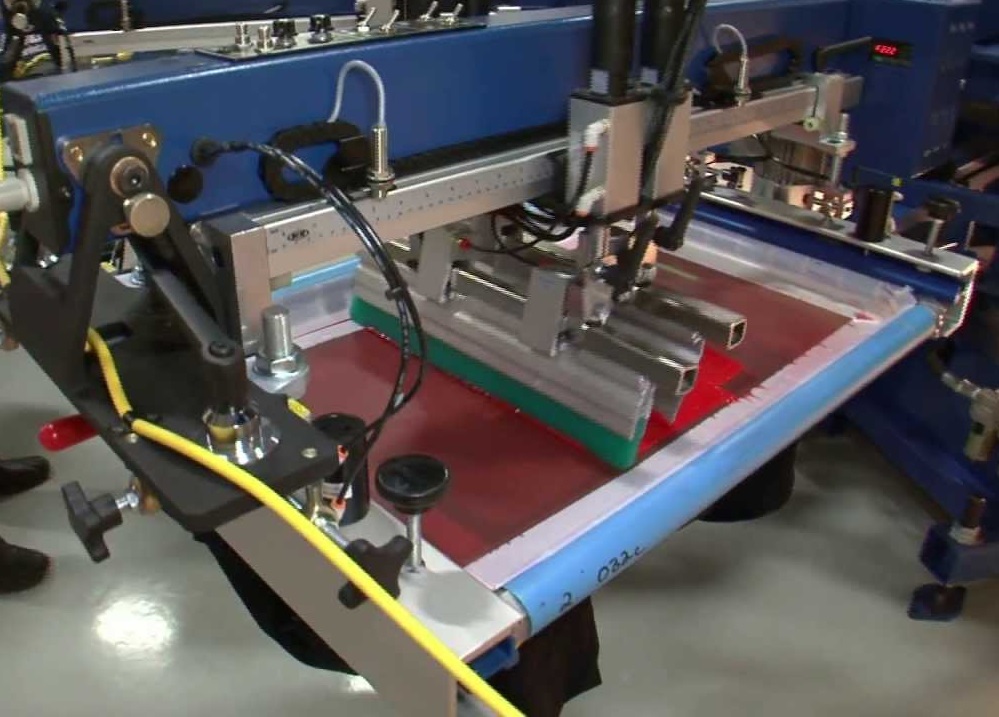

It is a fact of the process and you will note it even with one of the best of procedures and chemical substances. However, with the choice of applicable, high-quality products, and correct application, you will go a long way towards minimizing haze, stains and ghosts. Screen printing ink dries fairly rapidly, and if you wish to use the same silk screen again, then you want to wash it out with cold water immediately after printing so that none of the ink dries within the design. To print a number of copies of the display design on clothes in an environment friendly method, newbie and skilled printers normally use a display screen printing press. Many companies offer simple to stylish printing presses. These presses come in considered one of three varieties, Manual , Semi-Automatic, and Fully Automatic. Most printing corporations will use one or more semi-automatic or fully computerized machines.

This is the one approach to make high-build absolutely patterned printing/coating as a continuous process, and has been widely used for manufacturing textured wallpapers. Essentially, digital hybrid display printing is an automated screen-printing press with a CMYK digital enhancement situated on one of the display print stations. Digital hybrid screen printing is able to variable information options, creating endless customizations, with the added ability of screen print particular techniques. Texsource sells more brands than some other US provider - leading manufacturers from across the screen printing industry. We carry display printing ink from Union, Rutland, Matsui, Triangle, International Coatings, and our own GEN Series inks. If you are on the lookout for screen printing equipment, we carry solely one of the best; manufacturers like Workhorse, Vastex, Hix, Black Body, Stahls, Geo Knight, and Genesis.

Please see our designer silkscreen web page for directions of tips on how to use our customized silkscreens. When it comes to the display, every thing depends on the standard of the display screen. Good quality screens can be costly, but they are often cleaned simply and likewise they can work nicely for a longer duration. These screens are good for projects with fine particulars and which require higher tensions. The retensionable display permits you to enhance the tension of your screen as per your requirement. Aluminum screens are a extra dependable display screen as compared to the wood screens. Our skilled staff can print any artistic artwork you presumably can provide you with.

Traditionally, the process was known as screen printing or silkscreen printing as a end result of silk was used within the process. Currently, artificial threads are commonly used in the display printing course of. There are special-use mesh materials of nylon and stainless steel obtainable to the screen-printer.

Credit is given to the artist Andy Warhol for popularising display screen printing as a creative technique. Warhol's silk screens include his 1962 Marilyn Diptych, which is a portrait of the actress Marilyn Monroe printed in daring colours.

This hardens the emulsion in the exposed areas but leaves the unexposed elements gentle. They are then washed away utilizing a water spray, abandoning a clear space in the mesh with the identical form as the desired image, which is in a position to permit passage of ink. Texsource provides both wood and aluminum screen printing frames in a large number of sizes and mesh counts. The most necessary a part of this step is to make use of high quality products when reclaiming screens! Some printers use family cleansing provides, like Mineral Spirit, to take away ink from their screens. When it comes right down to it, the cheap chemical compounds are actually dearer to use.

Screens on the decrease end of the mesh rely spectrum put down heavier ink deposits and are perfect for printing underbases or printing daring colours on dark materials. At the higher end of the mesh count spectrum, you can print a more detailed image while sustaining a fair ink deposit. Screen printing is a printing approach where a mesh is used to transfer ink onto a substrate, besides in areas made impermeable to the ink by a blocking stencil. A blade or squeegee is moved throughout the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the display to the touch the substrate momentarily along a line of contact. This causes the ink to wet the substrate and be pulled out of the mesh apertures as the display screen springs back after the blade has handed. One color is printed at a time, so a quantity of screens can be utilized to supply a multi-coloured image or design. The present paper compares the properties of varied display material for printing thick film inks and pastes required to delineate thick movie integrated circuits.

Both wooden and metallic will finally lose their tension, however metal can be stripped and re-screened for long-term use.

A pressure washer helps take away material and may help conserve sources by quickly transferring chemicals, inks and emulsion with out overusing cleaning chemistry and rinse water. Spread your ink about two inches above your artwork fully throughout the width, and use the squeegee to slowly, firmly and with strong, solid strain, push the ink down and over the design. Push the squeegee up, down, facet to aspect, to fully press the ink by way of the design and onto your t-shirt (or canvas bag, or whatever you're printing on). Slowly pull the screen away from your t-shirt, and let the shirt dry. A development of screen printing with flat screens from 1963 was to wrap the display screen around to type a tube, with the ink supply and squeegee inside the tube.

Ink is positioned on top of the display, and a floodbar is used to push the ink through the holes within the mesh. The operator begins with the fill bar at the rear of the screen and behind a reservoir of ink.

When a picture is placed on the emulsion and exposed to UV, a negative image is created. This is the stencil you utilize to seep ink by way of onto your substrate.

There are several totally different mesh counts that can be used depending on the element of the design being printed. Once a display is chosen, the screen should be coated with emulsion and dried. Most screens are prepared for re-coating at this stage, however typically screens will have to endure a further step within the reclaiming course of referred to as dehazing. This extra step removes haze or "ghost photographs" left behind within the display once the emulsion has been removed. Ghost pictures are inclined to faintly define the open areas of previous stencils, hence the name. They are the outcomes of ink residue trapped within the mesh, typically in the knuckles of the mesh .

For example, the Easiway Easisolv 701 N, is a display wash and stain remover. One chemical can be used in two completely different steps of the reclaiming screens process. I discovered these little $1.00 wooden picture frames at my native craft retailer and knew right away that they would make the right little screens.

Wooden screens and frames are good for those tasks that require simple prints, and that don’t require excessive accuracy. So with all these advantages and downsides, it's as a lot as you to make a correct selection about whether you need a wooden body or not. If your picture is merely too massive for the display dimension chosen, we'll downsize your image so it'll match appropriately within the silkscreen frame ordered.

For instance, a half ounce of premium chemical is equal to eight ounces of low-cost chemical ink remover. The low cost chemical will take so much longer to interrupt down the ink and may trigger injury to the screen. There are varied terms used for what is essentially the identical method.